International Journal of Advanced Ceramic Technology has published many of the most important and influential applied ceramic science, technology, and engineering papers. With the recent impactful changes to its editorial structure, ACT has positioned itself to publish even more high-quality articles while simultaneously focusing on author satisfaction.

ACT @ 20 highlights articles that exemplify the breadth and depth of advanced ceramic technology research published in ACT over its first 20 years.

As always, ACerS members get free access to these articles. ACerS and Wiley will make a few articles free-to-read each month.

Additive Manufacturing

| Stereolithographic ceramic manufacturing of high strength bioactive glass | R Gmeiner, G Mitteramskogler, J Stampfl, A R Boccaccini, |

| Additive manufacturing of dense alumina ceramics | M Schwentenwein, J Homa |

| Additive manufacturing of dense ceramic parts via direct Ink writing of aqueous alumina suspensions | L Rueschhoff, W Costakis, M Michie, J Youngblood, R Trice |

| Processing and 3D printing of SiCN polymer‐derived ceramics | M Mahmoudi, S Kim, A M Arifuzzama, T Saito, C L Cramer, M Minary-Joland |

| Martian regolith—Ti6Al4V composites via additive manufacturing | A Afrouzian, K D Traxel, A Bandyopadhyay |

Ceramic Matrix Composites

| SiC‐Matrix Composites: Nonbrittle Ceramics for Thermo‐Structural Application | R R Naslain |

| Ceramic Matrix Composites: A Challenge in Space‐Propulsion Technology Applications | S Schmidt, S Beyer, H Immich, H Knabe, R Meistring, A Gessler |

| Progress in Processing and Performance of Porous‐Matrix Oxide/Oxide Composites | R A Simon |

| Electrical Resistance as a Nondestructive Evaluation Technique for SiC/SiC Ceramic Matrix Composites Under Creep‐Rupture Loading | C E Smith, G N Morscher, Z Xia |

| Fatigue of three advanced SiC/SiC ceramic Matrix composites at 1200°C in air and in steam | M Ruggles-Wrenn, N Boucher, C Przybyla |

Bioceramics

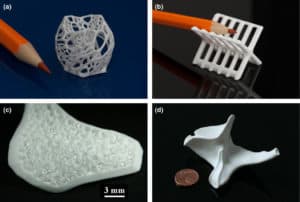

| Robocasting of silicon nitride with controllable shape and architecture for Biomedical applications | S Zhao, W Xiao, M N Rahaman, D O'Brien, J W Seitz-Sampson, B Sonny Bai |

| Bioactive sol‐gel glasses: Processing, properties, and applications | F Baino, E Fiume, M Miola, E Verné |

| Functionally graded ceramics for biomedical application: Concept, manufacturing, and properties | C Petit, L Montanaro, P Palmero |

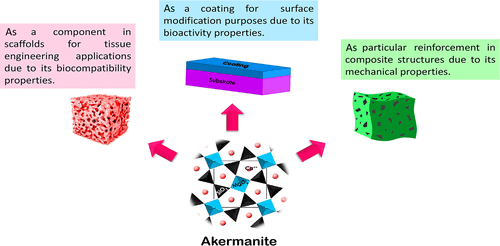

| Recent advances on akermanite calcium‐silicate ceramic for biomedical applications | P Zadehnajar, M H Mirmusavi, S S Eil Bakhtiari, H R Bakhsheshi-Rad, S Karbasi, S RamaKrishna, F Berto |

| Glass‐ceramics in the CaO–MgO–Al2O3–SiO2 system as potential dental restorative materials | K Dimitriadis, D Moschovas, D U Tulyaganov, S Agathopoulos |

Advanced Sintering

| Laser melting of spark plasma‐sintered zirconium carbide: thermophysical properties of a generation IV very high‐temperature reactor material | H F Jackson, D D Jayaseelan, W E Lee, M J Reece, F Inam, D Manara, C P Casoni, F De Bruycker, K Boboridis |

| A comparison between FAST and SPS apparatuses based on the sintering of oxide ceramics | J Langer, D V Quach, J R Groza, O Guillon |

| Influence of oxygen substoichiometry on the dielectric properties of BaTiO3‐δ nanoceramics obtained by spark plasma sintering | C Voisin, S Guillemet‐Fritsch, P Dufour, C Tenailleau, H Han, J C Nino |

| The effect of grain size on the mechanical and optical properties of spark plasma sintering‐processed magnesium aluminate spinel MgAl2O4 | A Rothman, S Kalabukhov, N Sverdlov, M P Dariel, N Frage |

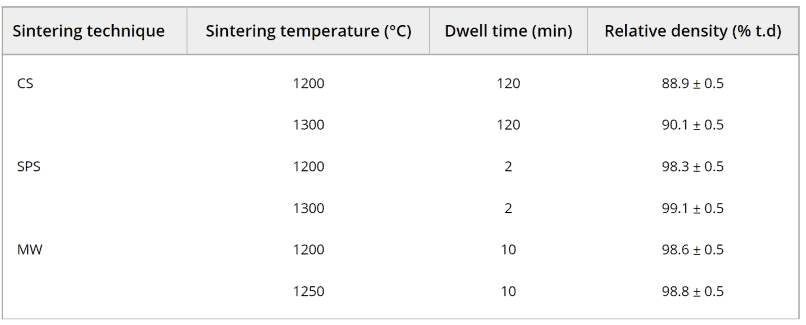

| Microwave, spark plasma and conventional sintering to obtain controlled thermal expansion β‐eucryptite materials | R Benavente, M D Salvador, O García‐Moreno, F L Peñaranda‐Foix, J M Catalá‐Civera, A Borrell |

High-Temperature Ceramics

| Fast densification of ultra‐high‐temperature ceramics by spark plasma sintering | A Bellosi, F Monteverde, D Sciti |

| Joining of ZrB2‐based ultra‐high‐temperature ceramic composites to Cu–clad–molybdenum for advanced aerospace applications | M Singh, R Asthana |

| Synthesis, microstructure, and mechanical properties of Ti3Sn(1−x)AlxC2 MAX Phase solid solutions | S Dubois, G P Bei, C Tromas, V Gauthier‐Brunet, P Gadaud |

| Synthesis of the MAX Phases by pulse discharge sintering | ZM Sun, H Hashimoto, W Tian, Y Zou |

| Ultra‐high‐temperature ceramic HfB2‐SiC coating for oxidation protection of SiC‐coated carbon/carbon composites | X Ren, H Li, Y Chu, Q Fu, K Li |

Thermal/Environmental Barrier Coatings

| New thermal barrier coatings based on pyrochlore/YSZ double‐layer systems | R Vaßen, F Traeger, D Stöver |

| Development of advanced low conductivity thermal barrier coatings | D Zhu, R A Miller |

| Thermal and environmental barrier coatings for SiC/SiC CMCs in aircraft engine spplications | I Spitsberg, J Steibel |

| Mechanical properties/database of plasma‐sprayed ZrO2‐8 wt% Y2O3 thermal barrier coatings | S R Choi, D Zhu, R A Miller |

| Research status of bond coats in environmental barrier coatings | Z Zhang, Y Park, Z Xue, S Zhang, E Byon, B-H Koo |

Ceramic Armor

| The role of dynamic material properties in the performance of ceramic armor | J Lankford Jr |

| Recommendations for determining the hardness of armor ceramics | J J Swab |

| Lightweight ballistic with additional stab protection made of thermally sprayed ceramic and cermet coatings on aramide fabrics | R Gadow, K Von Niessen |

| Flexural strength, fracture toughness, and hardness of silicon carbide and boron carbide armor ceramics | L Vargas‐Gonzalez, R F Speyer, J Campbell |

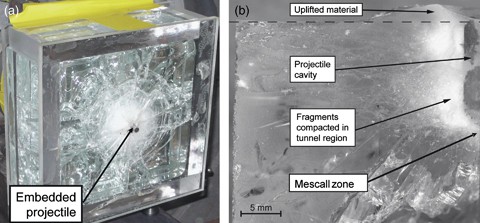

| The damage mechanism route to better armor materials | D A Shockey, J W Simons, D R Curran |

Porous Ceramics

| Properties of microstructure‐controllable porous yttria‐stabilized ziroconia ceramics fabricated by freeze casting | K H Zuo, Y-P Zeng, D Jiang |

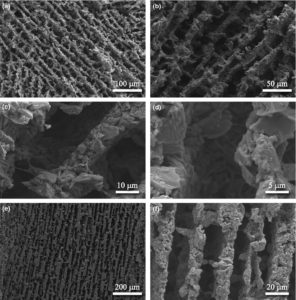

| Hierarchical structure of porous silicon nitride ceramics with aligned pore channels prepared by ice‐templating and nitridation of silicon powder | D S Kim, D K Kim |

| Controlling the microstructure of lyophilized porous biocomposites by the addition of ZnO‐doped bioglass | L Ciołek, M Biernat, Z Jaegermann, P Tymowicz-Grzyb, P Taźbierski, A Jastrzębska, A Olszyna |

| Processing methods for making porous bioactive glass‐based scaffolds—A state‐of‐the‐art review | F Baino, E Fiume, J Barberi, S Kargozar, J Marchi, J Massera, E Verné |

| Multi‐scale modeling for frequency‐dependent dielectric responses of non‐uniform porous carbon fiber/mullite composites | X Xia, S Zhao, L Long, Y Li, W Zhou |

Solid Oxide Fuel Cells

| Solid oxide fuel cells: Technology status | P Singh, N Q Minh |

| Sealing technology for solid oxide fuel cells (SOFC) | R N Singh |

| Regenerative performance of the NASA symmetrical solid oxide fuel cell design | T L Cable, J A Setlock, S C Farmer, A J Eckel |

| Glass ceramics sealants for SOFC interconnects based on a high chromium sinter alloy | J Schilm, A Rost, M Kusnezoff, S Megel, A Michaelis |

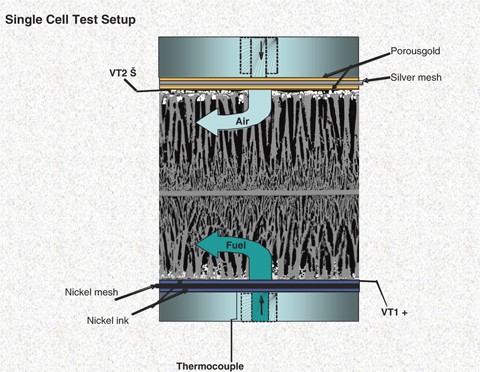

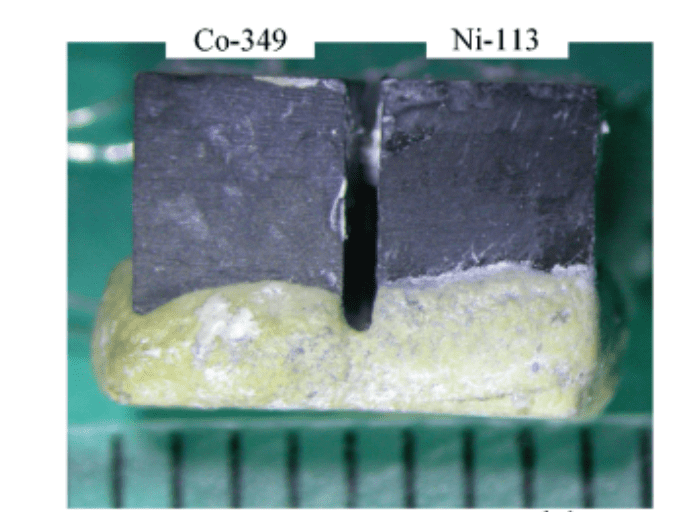

| Five-layer reverse tape casting of IT-SOFC | A L Snowdon, Z Jiang, R Steinberger-Wilckens |

Ceramics for Energy Storage (Battery)

| Development of sodium-sulfur batteries | T Oshima, M Kajita, A Okuno |

| Thermal behavior of delithiated Li1-xMnPO4 (0 = x <1) structure for lithium-ion batteries | J Yoshida, S Nakanishi, H Iba, H Abe, M Naito |

| Sintering behavior of garnet-type Li6.4La3Zr1.4Ta0.6O12 in Li2CO3 atmosphere and its electrochemical property | Z Huang, K Liu, L Chen, Y Lu, Y Li, C-A Wang |

| Characterization of vacuum-annealed TiNb2O7 as high potential anode material for lithium-ion battery | R Inada, T Mori, R Kumasaka, R Ito, T Tojo, Y Sakurai |

| Microstructure and ion conductivity of Al-LLZO solid electrolyte prepared by molten salt and cold sintering process | Y Zhang, A Liu, Z Shi, S Ge, J Zhang |

Thermoelectrics

| Critical overview of recent approaches to improved thermoelectric materials | B C Sales |

| Fabrication and application of an oxide thermoelectric system | R Funahashi, S Urata |

| Anisotropy of the mechanical and thermoelectric properties of hot‐pressed single‐layer and multilayer thick Ca3Co4O9 ceramics | D Kenfaui, D Chateigner, M Gomina, J Guillaume Noudem |

| Microstructure contact atudies for skutterudite thermoelectric devices | D Zhao, H Geng, L Chen |

| Effect of excess Ge and Te on Thermoelectric performance of GeTe | Y Dong, J Gao, P Zou, G Xu |

Piezoelectric and Dielectric Ceramics

|