Ceramics are used in transportation mainly because they are lightweight, can withstand high temperatures, are capable of insulating thermally and electrically, exhibit excellent wear and corrosion resistance properties, and are safe and reliable.

They can be found everywhere. Ceramic cam rollers, fuel injector pumps, valve discs for high-pressure injection systems, fuel pump rollers, particulate filters, modules for thermal insulation, and catalytic converters are located in the engine compartment. Ceramic coatings have also become quite common as thermal barrier coatings for components inside and outside the engine (e.g., intake manifolds, pistons, and cylinder heads) to improve fuel efficiency, horsepower, and general engine performance, and also to reduce exhaust emissions.

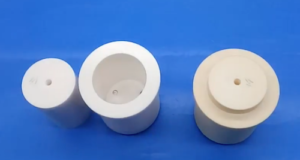

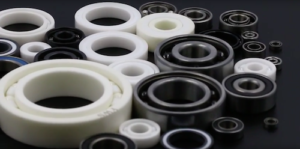

The power transmission/ drive train (or, simply, powertrain) system often includes ceramic clutches, bearings, balls, seals, valves, and piezoelectric actuators. Ceramic brakes, leveling valves, and piezoelectric components for vibration and noise suppression are becoming integral part of the chassis. Ballistic door panels are integrated in the body of police cars and other high-security vehicles.

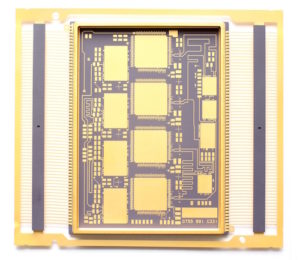

Spark plugs, passive components, and low-temperature co-fired ceramics (LTCCs) are the most relevant ceramic elements found in the electrical/electronic system. These systems are becoming increasingly important in transportation. In the 1970s, automotive electronics accounted for just 5% of the total cost of a car, whereas they are estimated to reach approximately 40% of the total cost in 2018. One of the main trends in the automotive industry is the shift towards semiautonomous and autonomous cars. The first self-driving cars are expected to be commercialized by 2020.

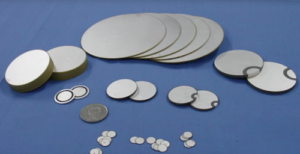

This will lead not only to increased demand for automotive electronic circuits but it will also positively affect demand for sensors. Vehicles contain a variety of ceramic-based sensors, such as oxygen, throttle position, fuel level, knock, temperature, pressure and acceleration sensors, which are critical to the proper functioning of all the automotive systems.

In addition, the automotive industry is evolving towards the use of power sources that are more environmentally friendly, and ceramics are finding application in the fabrication of gas turbines, fuel cells, and electric vehicles.

Glass is another important material for the transportation industry. Laminated and tempered glass is used for fabrication of windshields and passenger windows as well as sunroofs. Glass is also applied in the fabrication of rearview and side mirrors, light-emitting diode (LED) lighting systems, and privacy glass.

Other relevant trends that will contribute to the continued growth in the ceramic and glass content of motor vehicles in the near future are on-going efforts to reduce weight, the advent of electric vehicles, the rise in ride sharing, and increasing connectivity.

The principal benefits for reducing car weight are fuel savings and, in the case of electric vehicles, longer driving times before recharging. Ceramic matrix composites, metal matrix composites based on ceramic reinforcements, and glass fiber composites have been introduced to facilitate weight reduction. Lighter window glass, such as Gorilla glass, is being pursued for windows applications.

As the market shifts away from vehicles based on combustion engines, ceramics are being considered for manufacturing solid state electrolytes and separators for advanced batteries.

Ride sharing and connectivity will also contribute to increasing sales of smart glass and advanced displays for augmented reality and infotainment, as well as camera lenses and electronic components for smart traffic management, cloud-navigated cars, and Internet of Things (IoT) networking.

Solar reflective glass and glass for solar cells to be used as auxiliary energy sources are other products that are projected to become more relevant in the near future within the transportation industry.

The main applications of ceramics and glass in transportation are illustrated in the table below.

Main applications of ceramics and glass in transportation

| Where? | What? | Examples |

|---|---|---|

| CERAMICS | ||

| Engine compartment | Ceramic cam rollers | |

| Fuel injector pumps | 1  |

|

| Fuel pump rollers | ||

| Catalytic converter substrate | 2  |

|

| Thermal barrier coatings | 3  |

|

| Powertrain system | Ceramic clutches | 4  |

| Seals, valves, balls and bearings | 5  |

|

| Chassis | Ceramic brakes | 6  |

| Leveling valves (Image used with permission from CoorsTek) | 7  |

|

| Piezoelectric components | 8  |

|

| Body | Ballistic door panels (Image used with permission from CoorsTek) | 9  |

| Electrical/ electronic system | Spark plugs | 10  |

| Passive components (for example, resistors) | 11  |

|

| Low-temperature co-fired ceramics | 12  |

|

| Various | Sensors | 13  |

| GLASS | ||

| Body | Windshields, windows and sunroofs | 14  |

| Mirrors | 15  |

|

| LED lighting | 16  |

|

| Smart glass | 17  |

Image credits: 1. Wu Tina, YouTube; 2. AP Exhaust Technologies, YouTube; 3. zircotec.com, Wikimedia; 4. Engineering Explained, YouTube; 5. Yuki Bearing, YouTube; 6. Daderot, Wikimedia; 7. CoorsTek; 8. Beijing Ultrasonic, YouTube; 9. CoorsTek; 10. Pixabay; 11. Pixabay; 12. Konstantin Lanzet, Wikimedia; 13. Servoflo Corporation, YouTube; 14. theilr, Flickr; 15. Pixabay; 16. Thermos, Wikimedia; 17. india innovative, YouTube

Join The American Ceramic Society

Become an ACerS member and enjoy the additional benefits of belonging to a global community of ceramic and glass scientists, researchers, materials scientists, professors, students, and manufacturers.